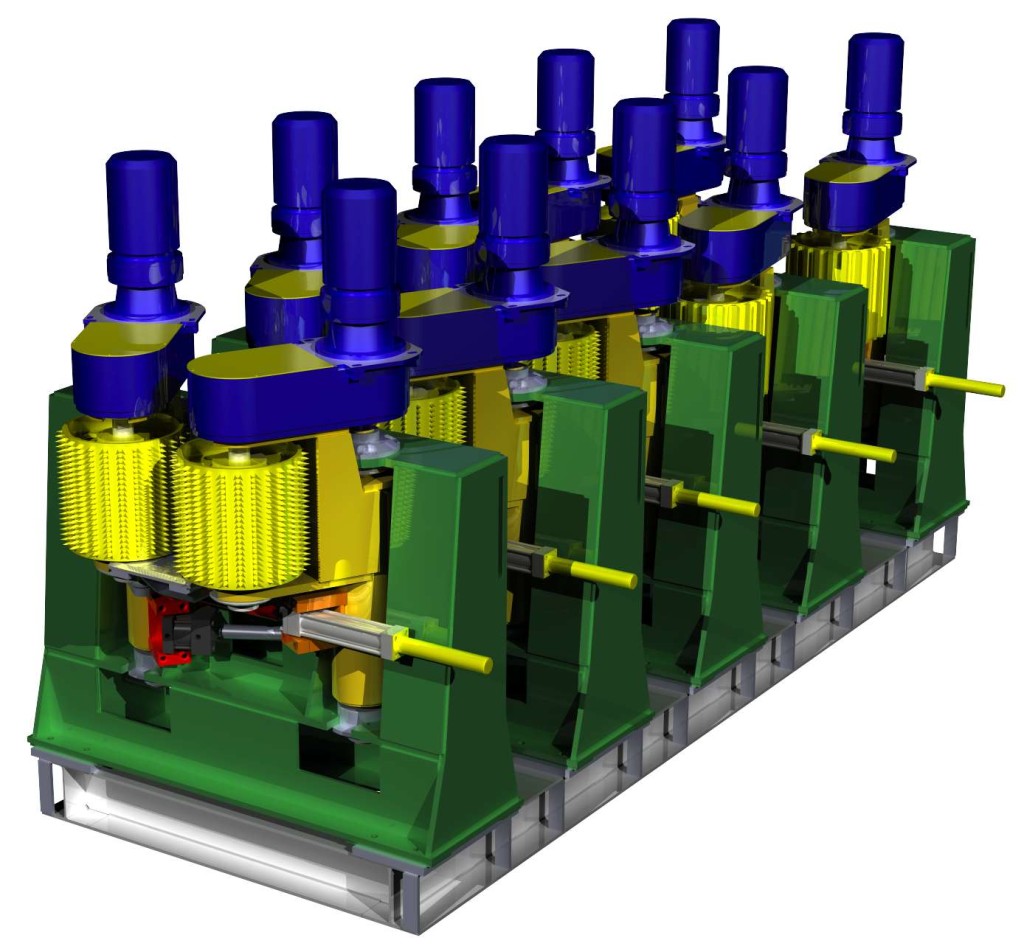

Vertical Roll Infeed model HE

Concept

Sawquip has developed this efficient 8’-16’ log infeed to replace existing infeeds that are space restrained and require accurate positioning to chipping canters and/or saws.

Operating Principle

The first two modules of the infeed have vertical bar rolls to permit final log turning as the log exits the log turner.

Subsequent roll assemblies have two mounted driven vertical spike rolls with each roll positioned against a log to transport it forward and ensure also that it remains in contact with the central anvil upon entering the chipping heads and/or saws.

The modular concept permits various log forms and diameters to be accommodated.

Drive assemblies

Individual rolls are driven by electric motor-reducers with pulleys and power belts. Drives are mounted over the rolls.

Vertical press rolls

The vertical press rolls are supported on pilot bearings at each end and are mounted on top and bottom steel fabricated pivoting assemblies. Each roll assembly is activated against a log by a hydraulic cylinder with controls.

Centering system

Each module with two vertical roll assemblies is able to maintain centering contact on a log by means of an inter-linkage between the rolls activated by a pneumatic cylinder assembly.

Central support anvil

The chromed steel central anvil supports a log as it moves forward and has a grooved, removable section between the last two vertical roll modules to assist in centering a log to the central anvil of a chipping canter and/or saws.

Mechanical maintenance

Maintenance and repairs of the various components are facilitated by easy access to all components of the vertical rolls, linkage and cylinder assemblies.

Advantages of the Modular HE Infeed

- Minimal footprint to facilitate installation in a restrained area

- Maintains the sawing axis of a log for best lumber recovery

- Can feed logs end to end

- Electric-mechanical drives for rolls

- No infeed chain

- Minimal maintenance and ease of access